Custom framework manufacture and restoration

The exposed coastal environment had resulted in extensive corrosion and loose components. The existing frame had corroded so badly that the hull had separated from the weathervane bearing and dropped down the cast iron column it was mounted on.

The entire 3m long weathervane was removed from the building to the Hall Conservation Ltd workshop, which required significant time and planning as the weathervane was located 40m up on the highest point of the building.

The iron frame was in such poor condition that we concluded it should be entirely replaced with 316 Stainless steel, made in sections to replicate the exiting design. The copper hull was carefully examined and templates made to assist in the manufacture of an accurate framework.

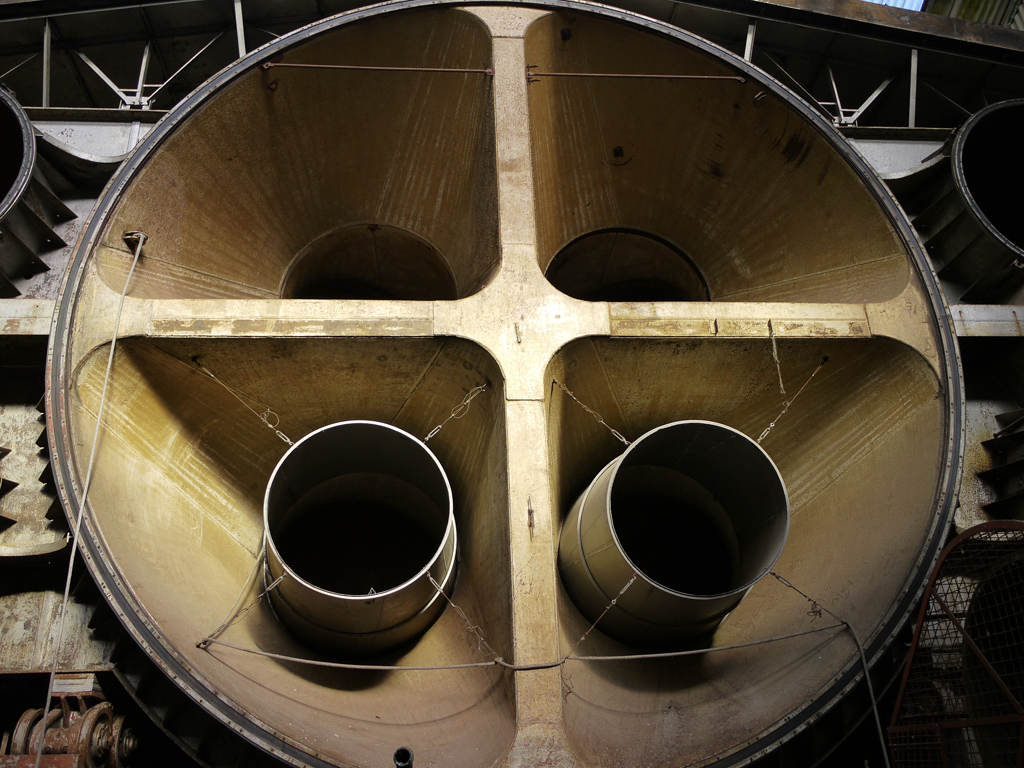

The beautifully patina on the external faces of the hull was carefully cleaned and hot waxed to protect it. The internal surfaces were cleaned to remove the expanding foam that had been installed previously, and then painted to protect and isolate it from the stainless steel. The original drainage holes were left open and and new sheet deck installed to prevent animal nesting.

Project Details

Role: Project Manager, Designer

Hall Conservation Ltd

Location: Portsmouth

Completed: February 2014