As part of the NHIG bursary course we were asked to manufacture a traditionally made piece of ironwork. The item had to be either replicated from an existing piece of pre 19th century ironwork or from a book of designs of a suitable age.

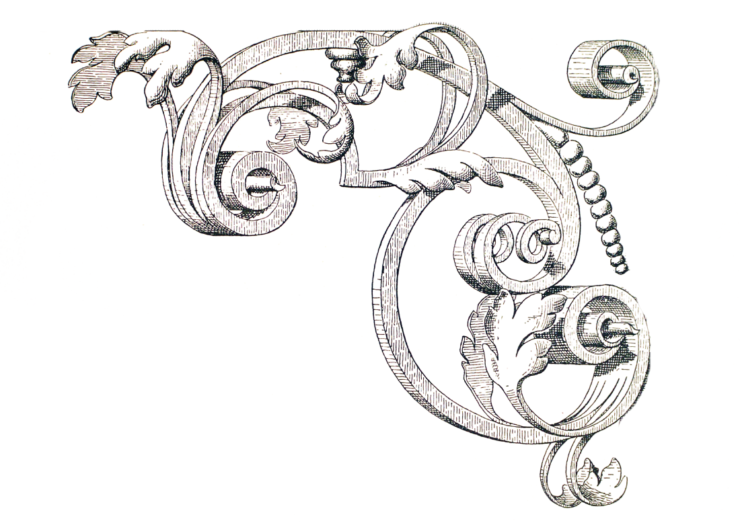

For my project I decided on a ornate bracket from a German book of 18th century ironwork designs titled ‘Die Schiedekunst. I do not know if these designs were copied from existing pieces at the time or just a collection of fanciful ideas.

For my project I decided on a ornate bracket from a German book of 18th century ironwork designs titled ‘Die Schiedekunst. I do not know if these designs were copied from existing pieces at the time or just a collection of fanciful ideas.

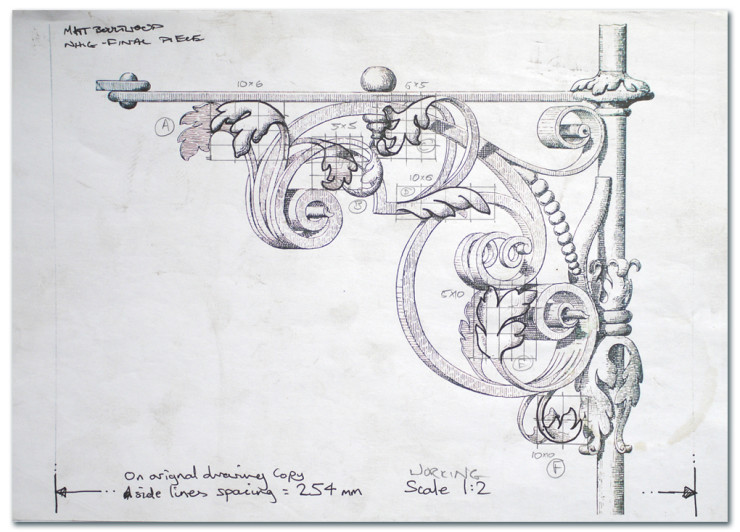

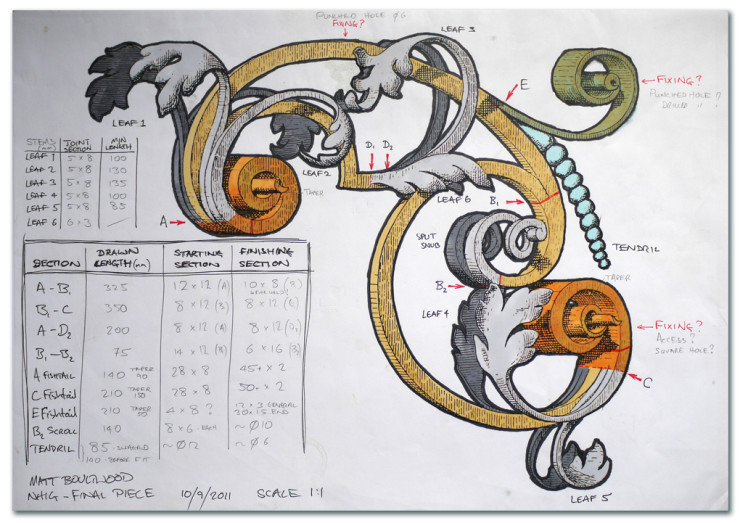

While working on the various placements of the NHIG course I was able to develop the design I found into a completed object. At the time the intricate nature of the design meant it was one of the most complicated blacksmithing projects I had undertaken. It recquired carefull planning in order to produce a faithfull recreation of the design in iron.

The final bracket s assembled into one piece by fire welding and manufactured from recycled wrought iron with pure iron leaves.